Freshpet

The Freshpet Kitchens project involved the construction of a new pretreatment wastewater plant in Bethlehem, PA.

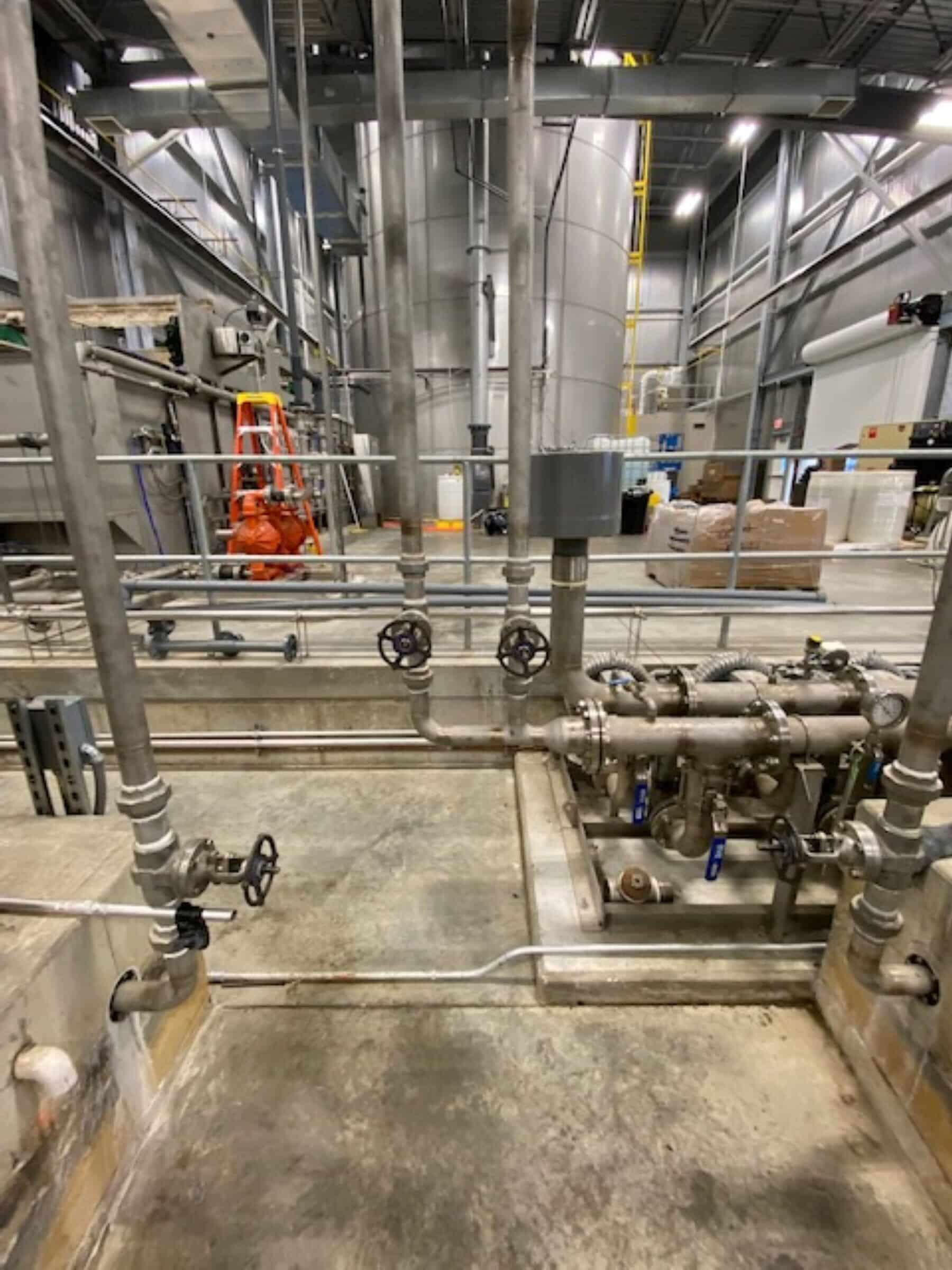

Worth & Company partnered with Keystone Engineering to install a new pretreatment wastewater plant at Freshpet Kitchens in Bethlehem, PA. The equipment installation included all the process piping, chemical pumps, process equipment handling and installation, and an odor control system to allow odors to be removed from the building.

- One (1) skid mounted blower unit (for grease trap)

- Four (4) sparge piping assemblies (for grease trap)

- Four (4) submersible pumps and railings (for grease trap)

- One (1) 2,500-gallon tank (wastewater transfer/holding)

- One (1) rotary drum screen – to be mounted on 2,5000-gallon tank

- One (1) skid mounted blower unit (for 2,500-gallon tank)

- One (1) clean-in-place hot water tank and pump (for rotary screen)

- One (1) skid mounted wastewater transfer pump assembly (to EQ tank)

- One (1) skid mounted blower unit (for equalization tank)

- One (1) skid mounted wastewater transfer pump assembly (to DAF system)

- One (1) dissolved air flotation (DAF) system

- One (1) skid mounted sludge transfer pump assembly

- One (1) 4,400-gallon sludge storage tank

- One (1) solids conveyor system (convey screened solids from rotary screen

Worth & Company’s Industrial team utilized its vast resources and innovative technology to provide all required piping, fittings, valves, couplings, pipe and valve supports, testing, and connections to the wastewater treatment plant equipment to facilitate a complete installation and functioning system ahead of schedule.

Related Approaches

- Pre-Construction

- Virtual Design & Construction (VDC)

Related Attribute

- Fabrication

New Business Inquiries

Please reach out to discuss your project, and learn about our Industrial Construction capabilities.